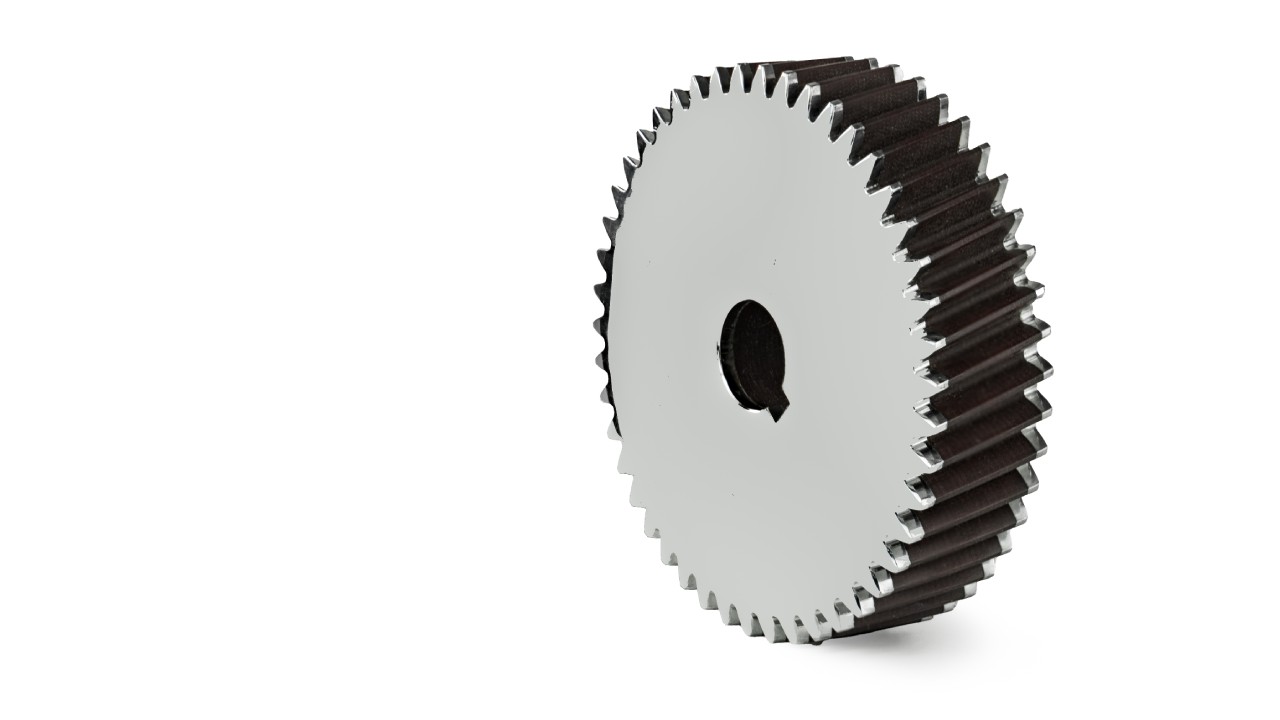

Spur Gears

Spur gear products can be designed as a complete or segment gear and manufactured according to the specifications of the application – custom or build-to-print. We have the ability to manufacture commercial, hobbed, shaped, or precision ground internal and external gears with virtually any complexity and a variety of materials.

Helical Gears

Davall Gears can produce internal and external gears with a helix tooth as complete gears or segments to varying grades and qualities, from commercial gears, hobbed, or shaped, to precision ground gears. Parts are made of any complexity and a variety of materials to suit your application.

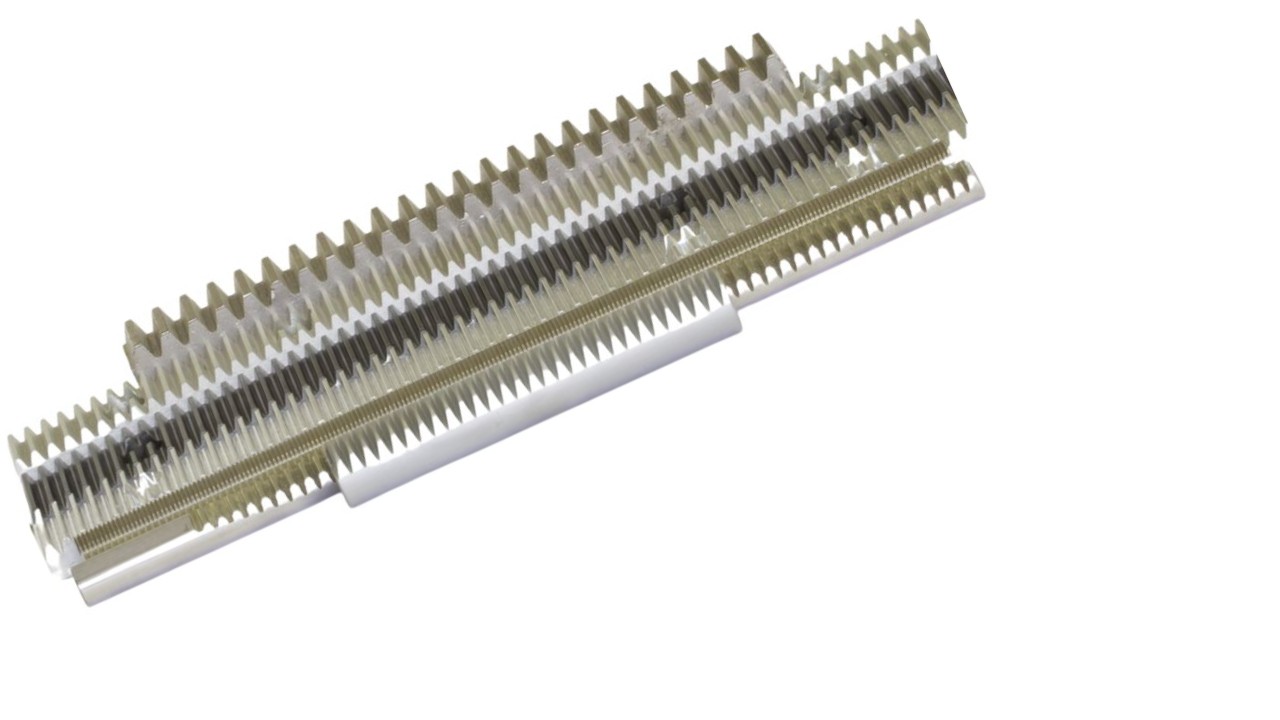

Racks

Straight racks are manufactured with a generated tooth form that is not milled. These tooth forms can be fashioned to any shape, made of these typical materials: Delrin, Brass, Steel, Titanium, or Stainless Steel. In addition, we can supply Straight Racks with processed ends for continuous long-run mounts.

Bevel Gears

Davall Gears manufactures straight tooth bevel, hypoid, spiral bevel gears, and mitre and ratio sets utilizing Coniflex® and other machining technology. We can manufacture mitre 1:1 (one-to-one) or ratio (crown wheel and pinion) gears to order. Our gears possess either the conventional 90° shaft angle or differing angles machined into materials that can be hardened to suit the application.